|

| |

Technical Digest

|

| Variable Speed Screw Compressor |

Raising The Bar For Variable Speed Performance |

| In this issue of INSIGHTS, we will take a deep look on the technical differences between screw rotor and centrifugal impeller, and explain why there is an application advantage on screw compressor when variable speed application (VFD) is applied to save energy. |

| Today’s building owners and managers require well-engineered solutions to keep long-term operational costs under control. The ability to lower heating and cooling costs is critical to this goal. The American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) estimates that 50% of all building energy is consumed by HVAC operation. |

Variable Frequency Drives

Variable frequency drives (VFDs) prevent wasting energy by precisely matching motor speed with cooling requirements, which results in dramatic reductions in power usage.

Affordable and factory installed in most cases, VFDs are one of the most cost-effective ways to maximize efficiency and reduce operating costs. According to ARI (Air Conditioning and Refrigeration Institute) Standard 550/590-2015, chillers typically run 99% of the time at part-load (off design conditions). Therefore, having your chiller match your building’s load profile will provide both efficiency and comfort.

To date, variable speed centrifugal compressors have been the best means to effectively reduce energy

consumption during the majority of the operational hours. When variable speed is applied to a screw compressor, the savings are increased, since the variable speed screw chiller always provides the maximum amount of speed reduction.

In order to fully appreciate the benefits of variable speed screw water-cooled chillers, an understanding

of centrifugal water-cooled chillers is required. |

Centrifugal Compressors

Centrifugal compressors are dynamic compression devices that continuously exchange angular momentum between a rotating impeller and steadily flowing refrigerant. As refrigerant molecules are accelerated outward by centrifugal force, new ones are drawn into the compressor to replace them. The overall effect is one of continuously compressing a stream of refrigerant. |

|

| Centrifugal compressor

impeller and diffuser. |

|

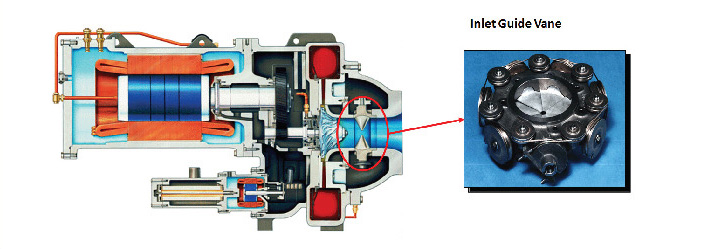

Why Inlet Guide Vanes Are Used In Variable Speed Applications? |

|

The most common form of capacity control for constant speed centrifugal chillers is to modulate guide vanes at the impeller inlet (also called pre-rotation vanes). As load is decreased, the mass flow of refrigerant moving through the compressor must be reduced. On constant speed machines, the guide vanes are closed to match compressor capacity to the load. When centrifugal machines are equipped with VFDs, speed control can also be used to control capacity. In this case both the impeller speed and the inlet guide vane can be reduced to match the compressor capacity to the load.

Inlet guide vane like mechanical unloaders of any kind introduce inefficiency. So while speed reduction is almost always obtained with any reduction of lift or load requirements, the question becomes one of magnitude. The amount of capacity reduction performed by speed reduction, relative to the amount of capacity reduction performed by guide vanes is an indication of the centrifugal chillers ability to capture all theoretical savings at a given operating point. Conversely, the more the guide vanes are closed, the higher the amount of inefficiency introduced into the system.

Given the cubic relationship of speed and power even a small amount of speed reduction yields a significant reduction in energy. However, the more speed reduction possible, the greater the energy savings. |

Understanding Screw Compressors

|

|

| Conventional twin screw compressor. |

|

The screw compressor is classified a positive displacement compressor, which simply means that a volume of gas is trapped with an enclosed space whose volume is then reduced. Conventional rotary screw compressors are composed of two parallel rotors with external helical profiles fit into a casing. |

One of the rotors is coupled to the motor (drive rotor) and as it turns it moves the other rotor (driven rotor), similar to a common gear set. The geometric profile of the rotating rotors is difficult to visualize. It is easier to relate the compression process to a reciprocating compressor, if you consider the drive rotor as the piston and the driven rotors as the cylinder. As the drive rotors and driven rotors unmesh, an empty cylinder is created, drawing in suction gas through the synchronized opening on the rotor suction face. As rotation continues, the suction and discharge rotor faces are sealed off, trapping the gas in the cylinder. When this happens, the meshing point moves toward the discharge end of the rotors and drives the gas ahead of it. The discharge port provided for the gas escape is relatively small, compared to the suction port, resulting in positive displacement compression.

Rotary screw compressors are well known for their robustness, simplicity, and reliability. They are designed for long periods of continuous operation, needing very little maintenance. Screw compressors can overcome high lift when speed is reduced, allowing energy savings without the possibility of surge as the compressor unloads. |

Variable Speed Screw Compressors

For positive displacement compressors, speed is independent of lift, or worded another way, the compressor can develop the same amount of lift at any speed. Therefore, mechanical loaders can be replaced entirely by speed control. Centrifugal compressors however may require speed control coupled with some closure of the inlet guide vanes. The variable speed screw compressor never has to temper speed control with a guide vane or slide valve, and therefore captures the maximum energy reduction available at a given operating condition. Even small changes in speed create significant changes in energy consumption. Combine this incremental advantage with superior compression efficiencies, and a clear picture of the energy savings potential of this technology emerges. |

VFD Chiller For Humid Climates

Applications where high lift requirements remain even as cooling loads decrease may favor variable speed screw chillers more significantly. An example of this application is a building located in a hot and humid climate where cooling loads can vary while outdoor-air temperatures (dry bulb/wet bulb) remain high.

A variable speed screw compressor chiller is approximately 10 to 20% more efficient than all variable speed centrifugal compressors with constant 29.4 deg.C entering condenser water.

To select the right chiller for your building, owners and operator should understand the importance of using system par load performance for your specific application. The unit with the lowest system part load performance will provide the greatest energy savings across its entire operational range. A variable speed screw compressor chiller saves energy in all operating conditions. |

Features |

Variable Speed

Centrifugal Compressor |

Variable Speed

Screw Compressor |

| Design |

Rotating impeller |

Helical screw compressor |

| Compression |

Dynamic Compression |

Positive displacement compression |

| Compressor Stall |

Surge at low speed (lift) |

Free from surge |

| Capacity Reduction |

IGV unload + speed reduction |

Speed reduction |

| Input Power Reduction |

proportion to Cubic of speed |

proportion to Cubic of speed |

Reference

Reindl, Douglas T. and Todd B. Jekel. “Screw Compressors: Selection Considerations for Efficient Operation.” Paper presented at the 21st IIR (International Institute of Refrigeration) International Congress of Refrigeration, Washington, D.C., 17-22 August 2003. |

This paper is published by Carrier Corporation Syracuse, New York. |

|

| Interested in technologies and solutions mentioned in this story? |

| Reach our Program Director |

|

|

|

| |

|

Feel free to share this newsletter with other building owners or

operators you know who may like to be part of our conversations. |

|

Click here to sign up for the "Engineering Upgrade for Large Buildings" Program if you haven't

Want to change how you receive these emails? You can unsubscribe from this list.

Copyright © United Technologies. All rights reserved. |

|

|

|

|